NEWS

Industry News

Proper maintenance preserves performance of gas turbines

Time:13 Jan,2016

A well planned maintenance programme will deliver continued reliability, optimum performance and improved efficiency

A well planned maintenance programme will deliver continued reliability, optimum performance and improved efficiency

Skilled engineers combined with expertise in material science and precision engineering can deliver cost effective repairs

Skilled engineers combined with expertise in material science and precision engineering can deliver cost effective repairs

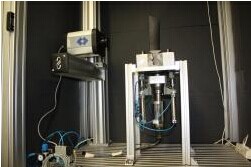

Active, lock-in thermography uses ultrasonic excitation to help detect flaws in components such as turbine blades

Gas turbines form a crucial part of many power generation facilities and provide an efficient and reliable power source that can be brought online as required. Maintaining that facility requires a well planned maintenance program that will deliver continued reliability, optimum performance and efficiency as well as enabling improvements to be implemented.

Although the operating principle of a gas turbine is relatively simple, the components involved in producing the energy are highly specialised and operate within very fine tolerances. The original equipment manufacturers (OEMs) provide a complete set of baseline performance data that can be compared to the information collected during each maintenance inspection. Variables such as vibration, pressures, temperatures and output are collated and analysed to produce a serviceability report.

Anomalies in the collected data can be assessed and prioritised to ensure that issues can be addressed before they cause significant damage. In this way the availability of the asset is maximised and repairs are completed during scheduled shut-down periods. These also present an opportunity for the operator to install upgrades and improvements that will ensure continued reliability and maintain or even improve performance; all of which can be managed and installed by engineers from Sulzer.

High temperature components

Gas turbine components are subjected to high temperatures, as well as high stress levels and are exposed to corrosive combustion gases at the same time. Gas turbines have to be fired to highest permissible temperatures to get the best efficiency and the highest output. Fighting degradation of components exposed to high temperature is a continuous challenge.

Many gas turbine hot-section components have a limited lifetime. Oxidation, corrosion, material degradation, and thermal cracking are the usual lifetime determining processes. A limited lifetime can be caused by the deterioration of only one detail of a component. A thorough analysis and understanding of the mechanism can lead to accurate pinpointing of that detail and to ways to improve the lifetime of the component. Improvements can be made on existing service-exposed components as well as in new designs.

Thermal imaging

Inspections of the hot, turbine section are essential and close examination of the individual turbine blades can reveal issues with overheating. Initial inspections by an experienced service engineer using a borescope can reveal more obvious defects but sometimes a more detailed inspection will be required.

The use of thermographic equipment to detect heat build-up in bearings and electrical connections uses a passive approach which relies on the thermal radiation of the object being examined. However, an active, lock-in thermography uses ultrasonic excitation to introduce energy into the object, such as a turbine blade, and measures its response. If the normally homogeneous material is damaged, some of the wave energy is absorbed and heat is generated, which can be detected by the thermal imaging camera. This can be executed during a component refurbishment cycle.

For turbine components, cooling is very important to extend and protect component life. During the repair of vanes or blades with cooling channels, it must be ensured that all the cooling holes are open. An infrared camera can show at a glance whether cooling holes are blocked or open and images can be recorded as part of the final repair report.

Repair technology

The sophisticated designs of the advanced technology components used in the hot sector of third generation gas turbines have presented significant challenges to the aftermarket repair sector. Many of the standard repair processes could not be applied to such complex designs. New welding techniques, coating materials, inspection procedures and tooling are necessary to restore components to a safe and serviceable condition.

The combustion section includes components such as fuel nozzles, cowl caps, combustion liners, transition pieces and flow sleeves. These require specialist dimensional and non-destructive inspections to be completed before an advanced weld repair method is used to restore the component to its correct dimensions. This can involve parent metal bonding to restore wall thicknesses and repair minor cracks.

For the rotating components within the hot section, the advances made in laser welding have allowed many blades, which would have otherwise been scrapped, to be saved and returned to service. Laser welding allows rebuilding of fine details with limited excess material. At the same time, stronger and harder weld filler alloys can be used for demanding applications.

Thermal barrier coatings (TBC) can be applied to components to help them withstand the high operating temperatures of the gas turbine. They can be applied to combustion liners, transition pieces and also blades and vanes. More advanced, extreme temperature resistant TBCs have been developed for application on first-stage advanced technology turbine buckets.

The search for increased power output using higher turbine inlet temperatures over 1300 °C has led to the application of single-crystal (SX) materials for turbine blading. Without a suitable repair procedure, SX blades must be replaced at every major overhaul after approximately 24,000 operating hours. Based on the investigations and the advanced repair techniques developed by Sulzer, SX blades can be refurbished to an ’as-new’ condition. With the high-end repair technology and the know-how of Sulzer, users of SX blades can give a second life to these components and thereby achieve substantial savings.

The number of advanced gas turbines installed is increasing rapidly due to rising fuel costs and environmental regulations. Higher operating temperatures and mechanical stresses are creating the need for the use of advanced technology components and refurbishment processes. In general, refurbishment activities consist of the stripping and reapplication of the coating, the rebuilding of the geometry by welding, and the rejuvenation of the material condition through appropriate heat treatments. Advanced refurbishment procedures also include changes in materials, coatings, or designs, which should reduce the risks of failure or the reoccurrence of damage.

Active, lock-in thermography uses ultrasonic excitation to help detect flaws in components such as turbine blades

Gas turbines form a crucial part of many power generation facilities and provide an efficient and reliable power source that can be brought online as required. Maintaining that facility requires a well planned maintenance program that will deliver continued reliability, optimum performance and efficiency as well as enabling improvements to be implemented.

Although the operating principle of a gas turbine is relatively simple, the components involved in producing the energy are highly specialised and operate within very fine tolerances. The original equipment manufacturers (OEMs) provide a complete set of baseline performance data that can be compared to the information collected during each maintenance inspection. Variables such as vibration, pressures, temperatures and output are collated and analysed to produce a serviceability report.

Anomalies in the collected data can be assessed and prioritised to ensure that issues can be addressed before they cause significant damage. In this way the availability of the asset is maximised and repairs are completed during scheduled shut-down periods. These also present an opportunity for the operator to install upgrades and improvements that will ensure continued reliability and maintain or even improve performance; all of which can be managed and installed by engineers from Sulzer.

High temperature components

Gas turbine components are subjected to high temperatures, as well as high stress levels and are exposed to corrosive combustion gases at the same time. Gas turbines have to be fired to highest permissible temperatures to get the best efficiency and the highest output. Fighting degradation of components exposed to high temperature is a continuous challenge.

Many gas turbine hot-section components have a limited lifetime. Oxidation, corrosion, material degradation, and thermal cracking are the usual lifetime determining processes. A limited lifetime can be caused by the deterioration of only one detail of a component. A thorough analysis and understanding of the mechanism can lead to accurate pinpointing of that detail and to ways to improve the lifetime of the component. Improvements can be made on existing service-exposed components as well as in new designs.

Thermal imaging

Inspections of the hot, turbine section are essential and close examination of the individual turbine blades can reveal issues with overheating. Initial inspections by an experienced service engineer using a borescope can reveal more obvious defects but sometimes a more detailed inspection will be required.

The use of thermographic equipment to detect heat build-up in bearings and electrical connections uses a passive approach which relies on the thermal radiation of the object being examined. However, an active, lock-in thermography uses ultrasonic excitation to introduce energy into the object, such as a turbine blade, and measures its response. If the normally homogeneous material is damaged, some of the wave energy is absorbed and heat is generated, which can be detected by the thermal imaging camera. This can be executed during a component refurbishment cycle.

For turbine components, cooling is very important to extend and protect component life. During the repair of vanes or blades with cooling channels, it must be ensured that all the cooling holes are open. An infrared camera can show at a glance whether cooling holes are blocked or open and images can be recorded as part of the final repair report.

Repair technology

The sophisticated designs of the advanced technology components used in the hot sector of third generation gas turbines have presented significant challenges to the aftermarket repair sector. Many of the standard repair processes could not be applied to such complex designs. New welding techniques, coating materials, inspection procedures and tooling are necessary to restore components to a safe and serviceable condition.

The combustion section includes components such as fuel nozzles, cowl caps, combustion liners, transition pieces and flow sleeves. These require specialist dimensional and non-destructive inspections to be completed before an advanced weld repair method is used to restore the component to its correct dimensions. This can involve parent metal bonding to restore wall thicknesses and repair minor cracks.

For the rotating components within the hot section, the advances made in laser welding have allowed many blades, which would have otherwise been scrapped, to be saved and returned to service. Laser welding allows rebuilding of fine details with limited excess material. At the same time, stronger and harder weld filler alloys can be used for demanding applications.

Thermal barrier coatings (TBC) can be applied to components to help them withstand the high operating temperatures of the gas turbine. They can be applied to combustion liners, transition pieces and also blades and vanes. More advanced, extreme temperature resistant TBCs have been developed for application on first-stage advanced technology turbine buckets.

The search for increased power output using higher turbine inlet temperatures over 1300 °C has led to the application of single-crystal (SX) materials for turbine blading. Without a suitable repair procedure, SX blades must be replaced at every major overhaul after approximately 24,000 operating hours. Based on the investigations and the advanced repair techniques developed by Sulzer, SX blades can be refurbished to an ’as-new’ condition. With the high-end repair technology and the know-how of Sulzer, users of SX blades can give a second life to these components and thereby achieve substantial savings.

The number of advanced gas turbines installed is increasing rapidly due to rising fuel costs and environmental regulations. Higher operating temperatures and mechanical stresses are creating the need for the use of advanced technology components and refurbishment processes. In general, refurbishment activities consist of the stripping and reapplication of the coating, the rebuilding of the geometry by welding, and the rejuvenation of the material condition through appropriate heat treatments. Advanced refurbishment procedures also include changes in materials, coatings, or designs, which should reduce the risks of failure or the reoccurrence of damage.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue