NEWS

Industry News

NTN Exhibits at “nano tech 2016 15th International Nanotechnology Exhibition & Conference”

Time:25 Jan,2016

Date: January 27 (Wed) to 29 (Fri), 2016

Venue: Tokyo Big Sight

Booth No.: 6P-16 (East Hall 6, Robotics Zone)

Link to the official site: http://www.nanotechexpo.jp/index.html

NTN will run a booth at “nano tech 2016 15th International Nanotechnology Exhibition & Conference” with the theme “Proprietary advanced technology contributing to higher development efficiency and productivity!”

The booth will feature an exhibit of an integrated device combining the Desktop Type High-speed Microscopic Coating Applicator and 3D Microgeometry Measuring Machine, which will run demonstrations of high-speed ink coating and shape measurements.

Other exhibits that are useful in a wide range of applications from research and development through to mass-production include the Parallel Link High Speed Angle Control Equipment that is capable of high-speed, high-precision angle positioning, the High Precision Magnetic Angle Sensor capable of detecting absolute angles with high precision, and linear modules suited to the positioning stage.

We look forward to seeing you at the event.

Main exhibits

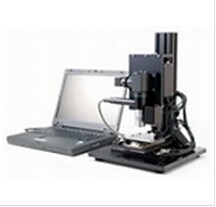

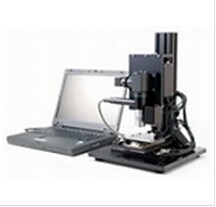

Desktop Type High-speed Microscopic Coating Applicator

Applies a few picoliter*1 droplets with high-accuracy, taking just 0.1 second per pass. Microscopic coating conditions and adjustments can be set on a PC monitor using a mouse. Installing multiple coating containers and coating needles*2 allows coating to be switched between liquid and paste. Optional extras also provide functions for measuring 3D shapes. An integrated device with coating and measurement functions will be on show at the event.

1. The installation size increases when multiple coaters are installed.

2. Desktop Type High-speed Microscopic Coating Applicator

3D Microgeometry Measuring Machine

Applies a few picoliter*1 droplets with high-accuracy, taking just 0.1 second per pass. Microscopic coating conditions and adjustments can be set on a PC monitor using a mouse. Installing multiple coating containers and coating needles*2 allows coating to be switched between liquid and paste. Optional extras also provide functions for measuring 3D shapes. An integrated device with coating and measurement functions will be on show at the event.

1. The installation size increases when multiple coaters are installed.

2. Desktop Type High-speed Microscopic Coating Applicator

3D Microgeometry Measuring Machine

Capable of measuring minute shapes of heights from a few µm to several 10µm generated on the surface of machined metal and resin materials, and glass and ceramic substrates at the fastest speed in its class. It is also capable of measurements at a visible range up to 1280µm × 960µm with high precision.

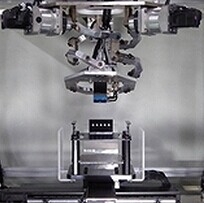

Parallel Link High Speed Angle Control Equipment

Capable of measuring minute shapes of heights from a few µm to several 10µm generated on the surface of machined metal and resin materials, and glass and ceramic substrates at the fastest speed in its class. It is also capable of measurements at a visible range up to 1280µm × 960µm with high precision.

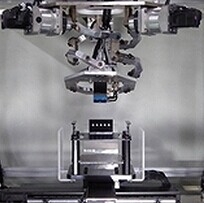

Parallel Link High Speed Angle Control Equipment

A compact device with operation over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. Stage and rotating axis combinations allow workpieces to be approached from various directions. Its structure allows the end effector and wiring to be placed within the hollow space inside links for a more compact device and wiring that is easier to use.

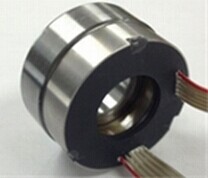

High Precision Magnetic Angle Sensor

A compact device with operation over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. Stage and rotating axis combinations allow workpieces to be approached from various directions. Its structure allows the end effector and wiring to be placed within the hollow space inside links for a more compact device and wiring that is easier to use.

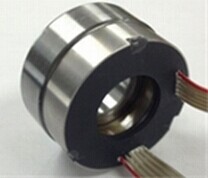

High Precision Magnetic Angle Sensor

A bearing with magnetic angle sensor with the magnetic encoder and magnetic sensor integrated with the bearing for high-precision detection of absolute angles. Integrating the magnetic encoder with the bearing ensures a more compact installation space and easier installation.

Linear module

A bearing with magnetic angle sensor with the magnetic encoder and magnetic sensor integrated with the bearing for high-precision detection of absolute angles. Integrating the magnetic encoder with the bearing ensures a more compact installation space and easier installation.

Linear module

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Applies a few picoliter*1 droplets with high-accuracy, taking just 0.1 second per pass. Microscopic coating conditions and adjustments can be set on a PC monitor using a mouse. Installing multiple coating containers and coating needles*2 allows coating to be switched between liquid and paste. Optional extras also provide functions for measuring 3D shapes. An integrated device with coating and measurement functions will be on show at the event.

1. The installation size increases when multiple coaters are installed.

2. Desktop Type High-speed Microscopic Coating Applicator

3D Microgeometry Measuring Machine

Applies a few picoliter*1 droplets with high-accuracy, taking just 0.1 second per pass. Microscopic coating conditions and adjustments can be set on a PC monitor using a mouse. Installing multiple coating containers and coating needles*2 allows coating to be switched between liquid and paste. Optional extras also provide functions for measuring 3D shapes. An integrated device with coating and measurement functions will be on show at the event.

1. The installation size increases when multiple coaters are installed.

2. Desktop Type High-speed Microscopic Coating Applicator

3D Microgeometry Measuring Machine

Capable of measuring minute shapes of heights from a few µm to several 10µm generated on the surface of machined metal and resin materials, and glass and ceramic substrates at the fastest speed in its class. It is also capable of measurements at a visible range up to 1280µm × 960µm with high precision.

Parallel Link High Speed Angle Control Equipment

Capable of measuring minute shapes of heights from a few µm to several 10µm generated on the surface of machined metal and resin materials, and glass and ceramic substrates at the fastest speed in its class. It is also capable of measurements at a visible range up to 1280µm × 960µm with high precision.

Parallel Link High Speed Angle Control Equipment

A compact device with operation over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. Stage and rotating axis combinations allow workpieces to be approached from various directions. Its structure allows the end effector and wiring to be placed within the hollow space inside links for a more compact device and wiring that is easier to use.

High Precision Magnetic Angle Sensor

A compact device with operation over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. Stage and rotating axis combinations allow workpieces to be approached from various directions. Its structure allows the end effector and wiring to be placed within the hollow space inside links for a more compact device and wiring that is easier to use.

High Precision Magnetic Angle Sensor

A bearing with magnetic angle sensor with the magnetic encoder and magnetic sensor integrated with the bearing for high-precision detection of absolute angles. Integrating the magnetic encoder with the bearing ensures a more compact installation space and easier installation.

Linear module

A bearing with magnetic angle sensor with the magnetic encoder and magnetic sensor integrated with the bearing for high-precision detection of absolute angles. Integrating the magnetic encoder with the bearing ensures a more compact installation space and easier installation.

Linear module

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue