NEWS

Industry News

NSK Develops the World's Lightest Electric Power Steering System

Time:15 Feb,2016

The lightest-ever electric power steering system, now continues to operate during an idle reduction and enhances safety

World's Lightest Electric Power Steering System

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed the world's lightest column-type electronic power steering* (EPS) system with the tilt, designed to contribute to fuel efficiency in automobiles. NSK plans to sell this product on a global scale for mid to small sized cars with a particular need for fuel efficiency.

*According to NSK research

Product Features

At the COP21 (21st session of the Conference of the Parties) in 2015, the international community agreed to a new climate change mitigation measures framework from 2020, reducing CO2 output, and enhanced activities for global environment protection. Strengthened exhaust gas regulations such as Euro-6 have already come into place in Europe. Combined with previous initiatives, this shows the increasing importance of automobile EPS systems on a global scale. In the development of EPS systems, it is vital to maintain safety, realize a compact, lightweight form that contributes to fuel efficiency, and enhances environmental performance.

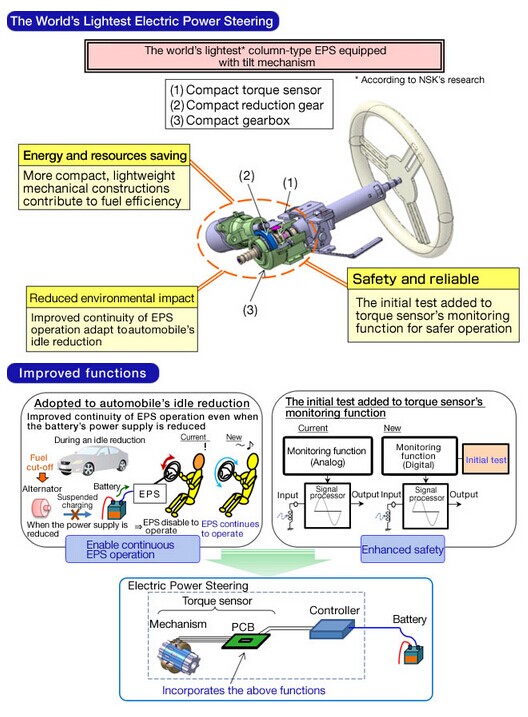

NSK has developed the world's lightest column-type EPS with tilt mechanism that enables adjusting position both up and down, as well as improving continuity of the operation and enhancing safety. With the internal mechanical constructions of the gearbox on this product made more compact, it is 13% lighter than current products. Also, the initial test improves safety via the torque sensor's monitoring function on start-up, and continuous EPS operation is possible even when the power supply from the battery is reduced during an idle reduction.

(1) Lightweight

Torque sensor: The mechanical constructions are optimal designed for more compact form.

Reduction gear: Analysis of the gear mesh results in optimal tooth surface is designed for more compact shape.

Gear box: Optimized casting design improves strength and stretching on materials, and realizes thin wall of gearbox.

(2) Improved continuity of EPS operation during an idle reduction

When there is an idle reduction, the power supply performance of the battery is potentially attenuated. To enable continuous EPS operation even when the voltage supplied from the battery is reduced, the drivable power of the torque sensor is changed to lower voltage.

(3) Enhanced safety

On current products, the EPS system operated by using the torque sensor's own monitoring function.

In addition to this, now the torque sensor's monitoring function also carries out the initial test on start-up. This feature improves EPS system safety.

Main Application

NSK will sell this product on a global basis for small to mid-sized automobiles.

Product Benefits

Its compact size and its compatibility with the need to shut down the engine when stopped both contribute to energy efficiency and resource saving.

Contributes to safety and security.

NSK is committed to the application of state-of-the-art technology for improved safety, comfort, and environmental performance of automobiles. Going forward, NSK plans to continue to grow the global sales of its steering technology business by improving its products and expanding local procurement and local production.

The lightest-ever electric power steering system, now continues to operate during an idle reduction and enhances safety

World's Lightest Electric Power Steering System

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed the world's lightest column-type electronic power steering* (EPS) system with the tilt, designed to contribute to fuel efficiency in automobiles. NSK plans to sell this product on a global scale for mid to small sized cars with a particular need for fuel efficiency.

*According to NSK research

Product Features

At the COP21 (21st session of the Conference of the Parties) in 2015, the international community agreed to a new climate change mitigation measures framework from 2020, reducing CO2 output, and enhanced activities for global environment protection. Strengthened exhaust gas regulations such as Euro-6 have already come into place in Europe. Combined with previous initiatives, this shows the increasing importance of automobile EPS systems on a global scale. In the development of EPS systems, it is vital to maintain safety, realize a compact, lightweight form that contributes to fuel efficiency, and enhances environmental performance.

NSK has developed the world's lightest column-type EPS with tilt mechanism that enables adjusting position both up and down, as well as improving continuity of the operation and enhancing safety. With the internal mechanical constructions of the gearbox on this product made more compact, it is 13% lighter than current products. Also, the initial test improves safety via the torque sensor's monitoring function on start-up, and continuous EPS operation is possible even when the power supply from the battery is reduced during an idle reduction.

(1) Lightweight

Torque sensor: The mechanical constructions are optimal designed for more compact form.

Reduction gear: Analysis of the gear mesh results in optimal tooth surface is designed for more compact shape.

Gear box: Optimized casting design improves strength and stretching on materials, and realizes thin wall of gearbox.

(2) Improved continuity of EPS operation during an idle reduction

When there is an idle reduction, the power supply performance of the battery is potentially attenuated. To enable continuous EPS operation even when the voltage supplied from the battery is reduced, the drivable power of the torque sensor is changed to lower voltage.

(3) Enhanced safety

On current products, the EPS system operated by using the torque sensor's own monitoring function.

In addition to this, now the torque sensor's monitoring function also carries out the initial test on start-up. This feature improves EPS system safety.

Main Application

NSK will sell this product on a global basis for small to mid-sized automobiles.

Product Benefits

Its compact size and its compatibility with the need to shut down the engine when stopped both contribute to energy efficiency and resource saving.

Contributes to safety and security.

NSK is committed to the application of state-of-the-art technology for improved safety, comfort, and environmental performance of automobiles. Going forward, NSK plans to continue to grow the global sales of its steering technology business by improving its products and expanding local procurement and local production.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue