NEWS

Industry News

Thordon’s Compac seawater-lubricated propeller shaft system nominated for major engineering award

Time:08 Mar,2016

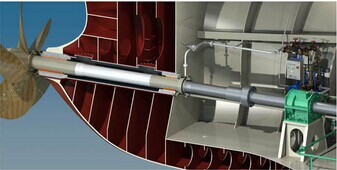

Thordon Bearing’s revolutionary COMPAC seawater-lubricated propeller shaft bearing system has been nominated in the Auxiliary Machinery category of the European Marine Engineering Awards, which will take place in Amsterdam, next month.

Craig Carter, Thordon Bearings’ Head of Marketing and Customer Service, said: “We are absolutely delighted that COMPAC has been nominated for such a prestigious award. Being proposed for an engineering award is testament to the advances our engineers and scientists have made in polymer technology.

Thordon Bearings’ COMPAC bearing system has been nominated for the European Marine Engineering Auxiliary Machinery Award

“The polymer we use in our COMPAC system is quite different from other material technology opted for in seawater-lubricated bearing systems,” added Carter. “Other bearing materials tend to have a life span of between five and seven years before they need replacing but our engineers have produced a polymer allowing us to offer a guaranteed bearing wear-life of 15 years. Current vessels using COMPAC are seeing even longer wear life.”

George Morrison, Thordon Bearings’ Regional Manager West Europe and Africa, said: “To be nominated for this award soon after winning the Tanker Shipping & Trade Environment Award last November is a remarkable achievement and illustrates the confidence that the market has in this technology.”

Last year Thordon Bearings’ COMPAC seawater-lubricated propeller shaft bearings were ordered for a number of significant commercial vessels. These included the two largest Jones Act containerships to be built, the 3600TEU vessels for Matson Navigation; the 38700dwt ‘eco’ bulk carrier Revelin for Atlantska Plovidba; and JT Cement’s Greenland, the world’s first ever LNG-fueled dry bulk ship.

Other nominees for Riviera Maritime Media’s European Marine Engineering Awards include ABB’s Azipod D and Wärtsilä’s Sternguard Seal. Nominees had to demonstrate a technological development that improves a vessel’s operational efficiency or reduces risk to personnel.

Thordon Bearings’ COMPAC bearing system has been nominated for the European Marine Engineering Auxiliary Machinery Award

“The polymer we use in our COMPAC system is quite different from other material technology opted for in seawater-lubricated bearing systems,” added Carter. “Other bearing materials tend to have a life span of between five and seven years before they need replacing but our engineers have produced a polymer allowing us to offer a guaranteed bearing wear-life of 15 years. Current vessels using COMPAC are seeing even longer wear life.”

George Morrison, Thordon Bearings’ Regional Manager West Europe and Africa, said: “To be nominated for this award soon after winning the Tanker Shipping & Trade Environment Award last November is a remarkable achievement and illustrates the confidence that the market has in this technology.”

Last year Thordon Bearings’ COMPAC seawater-lubricated propeller shaft bearings were ordered for a number of significant commercial vessels. These included the two largest Jones Act containerships to be built, the 3600TEU vessels for Matson Navigation; the 38700dwt ‘eco’ bulk carrier Revelin for Atlantska Plovidba; and JT Cement’s Greenland, the world’s first ever LNG-fueled dry bulk ship.

Other nominees for Riviera Maritime Media’s European Marine Engineering Awards include ABB’s Azipod D and Wärtsilä’s Sternguard Seal. Nominees had to demonstrate a technological development that improves a vessel’s operational efficiency or reduces risk to personnel.

Thordon Bearings’ COMPAC bearing system has been nominated for the European Marine Engineering Auxiliary Machinery Award

“The polymer we use in our COMPAC system is quite different from other material technology opted for in seawater-lubricated bearing systems,” added Carter. “Other bearing materials tend to have a life span of between five and seven years before they need replacing but our engineers have produced a polymer allowing us to offer a guaranteed bearing wear-life of 15 years. Current vessels using COMPAC are seeing even longer wear life.”

George Morrison, Thordon Bearings’ Regional Manager West Europe and Africa, said: “To be nominated for this award soon after winning the Tanker Shipping & Trade Environment Award last November is a remarkable achievement and illustrates the confidence that the market has in this technology.”

Last year Thordon Bearings’ COMPAC seawater-lubricated propeller shaft bearings were ordered for a number of significant commercial vessels. These included the two largest Jones Act containerships to be built, the 3600TEU vessels for Matson Navigation; the 38700dwt ‘eco’ bulk carrier Revelin for Atlantska Plovidba; and JT Cement’s Greenland, the world’s first ever LNG-fueled dry bulk ship.

Other nominees for Riviera Maritime Media’s European Marine Engineering Awards include ABB’s Azipod D and Wärtsilä’s Sternguard Seal. Nominees had to demonstrate a technological development that improves a vessel’s operational efficiency or reduces risk to personnel.

Thordon Bearings’ COMPAC bearing system has been nominated for the European Marine Engineering Auxiliary Machinery Award

“The polymer we use in our COMPAC system is quite different from other material technology opted for in seawater-lubricated bearing systems,” added Carter. “Other bearing materials tend to have a life span of between five and seven years before they need replacing but our engineers have produced a polymer allowing us to offer a guaranteed bearing wear-life of 15 years. Current vessels using COMPAC are seeing even longer wear life.”

George Morrison, Thordon Bearings’ Regional Manager West Europe and Africa, said: “To be nominated for this award soon after winning the Tanker Shipping & Trade Environment Award last November is a remarkable achievement and illustrates the confidence that the market has in this technology.”

Last year Thordon Bearings’ COMPAC seawater-lubricated propeller shaft bearings were ordered for a number of significant commercial vessels. These included the two largest Jones Act containerships to be built, the 3600TEU vessels for Matson Navigation; the 38700dwt ‘eco’ bulk carrier Revelin for Atlantska Plovidba; and JT Cement’s Greenland, the world’s first ever LNG-fueled dry bulk ship.

Other nominees for Riviera Maritime Media’s European Marine Engineering Awards include ABB’s Azipod D and Wärtsilä’s Sternguard Seal. Nominees had to demonstrate a technological development that improves a vessel’s operational efficiency or reduces risk to personnel.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue