NEWS

Industry News

NTN Exhibits at the “SIMTOS 2016”

Time:05 Apr,2016

Date: April 13 (Wed) to 17 (Sun), 2016

Venue: KINTEX, Goyang, Korea

Booth No. : Hall 1 02B960

Link to the official site: http://www.simtos.org/eng/Index.do

NTN will run a booth at the “SIMTOS 2016 (17th Seoul International Manufacturing Technology Show)” with the theme “Core Technology of Machine Tools, NTN,”with numerous exhibits including the ULTAGE* series of bearings as well as other products for machine tools.

Dynamic exhibits of linear modules will also be on show, and the booth will feature demonstrations of the Bearing Technical Calculation System for Machine Tool Spindles and maintenance tools.

We look forward to seeing you at the event.

* ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the [ULTIMATE] performance on any type of [STAGE.] It represents NTN's goal of achieving the ultimate performance with precsion bearings.

Main exhibits

ULTAGE series of precision rolling bearings for machine tools

Precision bearings responding to the need for improved efficiency, reliability, quality and environmental responsibility for machine tools. Optimization of the bearing's internal design, as well as special material and surface improvements, special grease and the use of seals on both sides deliver outstanding performance.

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Precision bearings responding to the need for improved efficiency, reliability, quality and environmental responsibility for machine tools. Optimization of the bearing's internal design, as well as special material and surface improvements, special grease and the use of seals on both sides deliver outstanding performance.

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Reduces the difference in temperature between the inner and outer rings with the use of an “air cooling spacer” using proprietary air cooling technology suited to bearing for main spindle of machine tools. This improves the high-speed rotational performance by 20% compared to conventional products (High-speed Angular Contact Ball Bearings), and achieves a dmn value of 2.1 million to achieve the world's highest standard high-speed rotational performance with air-oil lubrication and fixed-position preload.

Bearing Technical Calculation System for Machine Tool Spindles

Designed for precision rolling bearings used for machine tool spindles, this system that allows customers to quickly and automatically calculate main shaft rigidity, bearing operating life and other features. 10 types of main shaft patterns can be calculated, and the dedicated server operates 24 hours a day, 365 days a year for use at any time.

Ball Screw Support Unit

Reduces the difference in temperature between the inner and outer rings with the use of an “air cooling spacer” using proprietary air cooling technology suited to bearing for main spindle of machine tools. This improves the high-speed rotational performance by 20% compared to conventional products (High-speed Angular Contact Ball Bearings), and achieves a dmn value of 2.1 million to achieve the world's highest standard high-speed rotational performance with air-oil lubrication and fixed-position preload.

Bearing Technical Calculation System for Machine Tool Spindles

Designed for precision rolling bearings used for machine tool spindles, this system that allows customers to quickly and automatically calculate main shaft rigidity, bearing operating life and other features. 10 types of main shaft patterns can be calculated, and the dedicated server operates 24 hours a day, 365 days a year for use at any time.

Ball Screw Support Unit

Delivers the world's highest load capacity as a ball screw support unit, and uses a newly developed seal for low torque and high dust proofing. Comes filled with a long-life grease initially, eliminating the need for additional lubrication.

Linear module

Delivers the world's highest load capacity as a ball screw support unit, and uses a newly developed seal for low torque and high dust proofing. Comes filled with a long-life grease initially, eliminating the need for additional lubrication.

Linear module

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

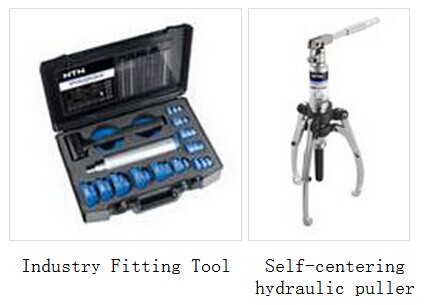

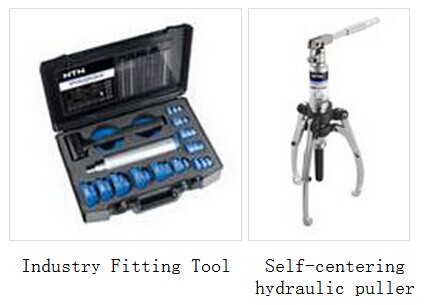

Maintenance tool

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Maintenance tool

A support tool to make work pressing and pulling bearings by customers at machinery maintenance and repair sites.

A support tool to make work pressing and pulling bearings by customers at machinery maintenance and repair sites.

Precision bearings responding to the need for improved efficiency, reliability, quality and environmental responsibility for machine tools. Optimization of the bearing's internal design, as well as special material and surface improvements, special grease and the use of seals on both sides deliver outstanding performance.

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Precision bearings responding to the need for improved efficiency, reliability, quality and environmental responsibility for machine tools. Optimization of the bearing's internal design, as well as special material and surface improvements, special grease and the use of seals on both sides deliver outstanding performance.

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Reduces the difference in temperature between the inner and outer rings with the use of an “air cooling spacer” using proprietary air cooling technology suited to bearing for main spindle of machine tools. This improves the high-speed rotational performance by 20% compared to conventional products (High-speed Angular Contact Ball Bearings), and achieves a dmn value of 2.1 million to achieve the world's highest standard high-speed rotational performance with air-oil lubrication and fixed-position preload.

Bearing Technical Calculation System for Machine Tool Spindles

Designed for precision rolling bearings used for machine tool spindles, this system that allows customers to quickly and automatically calculate main shaft rigidity, bearing operating life and other features. 10 types of main shaft patterns can be calculated, and the dedicated server operates 24 hours a day, 365 days a year for use at any time.

Ball Screw Support Unit

Reduces the difference in temperature between the inner and outer rings with the use of an “air cooling spacer” using proprietary air cooling technology suited to bearing for main spindle of machine tools. This improves the high-speed rotational performance by 20% compared to conventional products (High-speed Angular Contact Ball Bearings), and achieves a dmn value of 2.1 million to achieve the world's highest standard high-speed rotational performance with air-oil lubrication and fixed-position preload.

Bearing Technical Calculation System for Machine Tool Spindles

Designed for precision rolling bearings used for machine tool spindles, this system that allows customers to quickly and automatically calculate main shaft rigidity, bearing operating life and other features. 10 types of main shaft patterns can be calculated, and the dedicated server operates 24 hours a day, 365 days a year for use at any time.

Ball Screw Support Unit

Delivers the world's highest load capacity as a ball screw support unit, and uses a newly developed seal for low torque and high dust proofing. Comes filled with a long-life grease initially, eliminating the need for additional lubrication.

Linear module

Delivers the world's highest load capacity as a ball screw support unit, and uses a newly developed seal for low torque and high dust proofing. Comes filled with a long-life grease initially, eliminating the need for additional lubrication.

Linear module

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Maintenance tool

Linear motion units, which have small to large sized aluminum frames to special lightweight designs, are deployed with high-performance guide installed. The optimal type, size, stroke and drive method to suit applications such as processing machinery, work loaders of assembling machinery, and positioning equipment can be selected, while multiple units can be combined for a multi-axis layout in the X/Y/Z directions.

Maintenance tool

A support tool to make work pressing and pulling bearings by customers at machinery maintenance and repair sites.

A support tool to make work pressing and pulling bearings by customers at machinery maintenance and repair sites.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue