NEWS

Industry News

NSK Develops Insulated Bearings for Inverter Motors Used in General Industrial Machinery

Time:18 Apr,2016

Contributing to energy efficiency

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed insulated bearings for inverter motors used in general industrial machinery. This product is compatible with expanded use in inverter motors in order to save electricity, featuring optimized performance for use in inverter motors of general industrial machinery such as pumps, compressors, and fans.

NSK has enhanced bearing insulation, which has been a problem for inverter motors, and is targeting annual global sales of 1 billion yen in 2020.

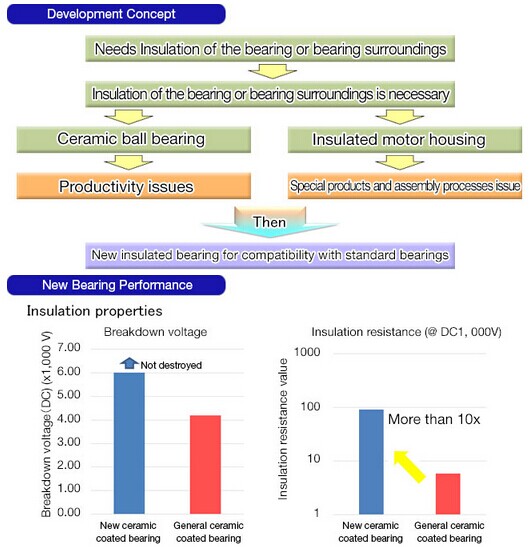

Development Background and Concept

In motors used in general industrial machinery, use of inverter control is expanding in order to increase efficiency. Along with this development, cases of a type of damage called electric corrosion* have been seen in bearings.

One way to prevent electric corrosion is to use non-conductive ceramic balls in bearings. However, productivity then becomes an issue. It is also possible to include an insulated housing in the motor, but this requires special parts and assembly processes. To solve these issues, NSK has developed a new insulated bearing that is highly productive and compatible with standard.

* Electric corrosion: When an electrical current passes along the contact point of the bearing races and rolling elements while the bearing is rotating, sparks are generated in the thin lubricant film and that surface is locally fused into an uneven shape.

Product Features

1. High insulation properties

To prevent electric corrosion in bearings, a highly productive aluminum ceramic coating material is used to coat the outer ring, and by combining optimized additives, insulation performance is improved by about tenfold.

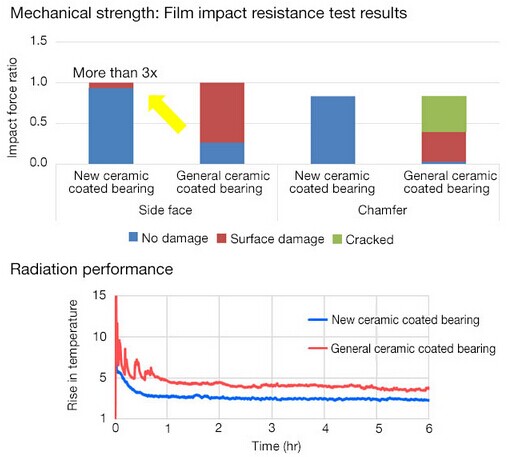

2. Improved durability

Optimizing bearing elements improves film impact resistance by a factor of 3x.

Optimized ceramic coating materials makes for excellent heat dissipation.

Product Benefits

The new product is designed to improve the reliability of motors in general industrial machinery, thereby contributing to the greater adoption of inverter motors.

NSK is targeting annual global sales of 1 billion yen for this product in 2020.

Lineup

Type:

Deep groove ball bearing, cylindrical roller bearing

Inner diameter:

50 mm to 110 mm

Dimensional deviation:

Compatible with traditional bearings

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue