NEWS

Industry News

NSK Developed Long-Life, optimized Cylindrical Roller Bearings for the Free Side of a Steel/Continuous Casting Machine Guide Roll

Time:27 Apr,2016

Introducing a new cylindrical roller bearing for continuous casting machines

NSK Developed Long-Life, optimized Cylindrical Roller Bearings for the Free Side of a Steel/Continuous Casting Machine Guide Roll

NSK Ltd. (NSK Headquarters, Tokyo, Japan; President and CEO Toshihiro Uchiyama) today announced "Long-Life, optimized Cylindrical Roller Bearings for the free side of steelmaking equipment and the free side guide rolls of continuous-casting machines. This new cylindrical roller bearing has a long life (reduces friction and absorbs roll deflection), smooth release of roll extension, and simple bearing assembly. This new bearing will contribute to high productivity and reduced maintenance costs for steelmaking equipment. NSK aims to sell approx. 1 billion yen of this product by 2018.

Development Background

A continuous casting machine shaped billets go through guide roll from melted iron. And many bearings are used in this guide roll. Continuous casting machines were requested stable operation, high productivity, and lower maintenance costs. To make a reply this request, guide roll bearings have to be long-life and highly reliable (to prevent sudden failure).However, guide roll bearings are operating with severe lubrication such as heavy loads, extremely low speeds and under the cooling water and steam circumstance. Especially, outside Japan manufacturer have some problems with early bearing damage. NSK developed new bearing which can reduce maintenance costs for continuous casting machine guide rolls.

Product Features

1. Long life (reduces friction problems and absorbs roll deflection)

Due to optimum roller crowing in this cylindrical roller bearing, it can reduce internal differential sliding friction compared to a SRB and absorb roll shaft bending. (Permissible misalignment; 12min)

2. Smoothly releases roll extension

Smooth relief of roll extension under high temperature condition.

3. Improved handling (non-separating structure using retaining ring)

Easy bearing mount by non-separate design with snap ring on inner ring.

Product Benefits

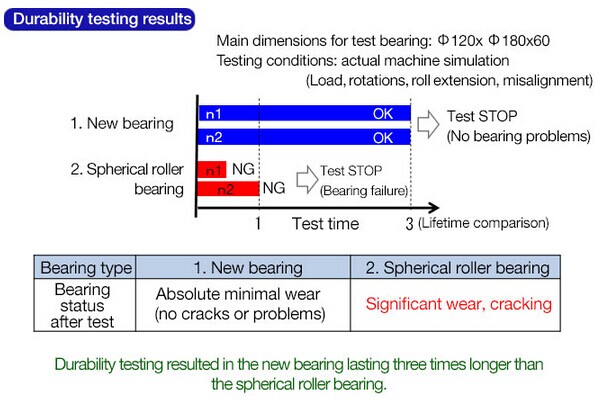

Compared to previous models, this product has three times longer life when used in the severe environment of continuous casting machine guide rolls, and make a contribution to improve steel productivity.

Introducing a new cylindrical roller bearing for continuous casting machines

NSK Developed Long-Life, optimized Cylindrical Roller Bearings for the Free Side of a Steel/Continuous Casting Machine Guide Roll

NSK Ltd. (NSK Headquarters, Tokyo, Japan; President and CEO Toshihiro Uchiyama) today announced "Long-Life, optimized Cylindrical Roller Bearings for the free side of steelmaking equipment and the free side guide rolls of continuous-casting machines. This new cylindrical roller bearing has a long life (reduces friction and absorbs roll deflection), smooth release of roll extension, and simple bearing assembly. This new bearing will contribute to high productivity and reduced maintenance costs for steelmaking equipment. NSK aims to sell approx. 1 billion yen of this product by 2018.

Development Background

A continuous casting machine shaped billets go through guide roll from melted iron. And many bearings are used in this guide roll. Continuous casting machines were requested stable operation, high productivity, and lower maintenance costs. To make a reply this request, guide roll bearings have to be long-life and highly reliable (to prevent sudden failure).However, guide roll bearings are operating with severe lubrication such as heavy loads, extremely low speeds and under the cooling water and steam circumstance. Especially, outside Japan manufacturer have some problems with early bearing damage. NSK developed new bearing which can reduce maintenance costs for continuous casting machine guide rolls.

Product Features

1. Long life (reduces friction problems and absorbs roll deflection)

Due to optimum roller crowing in this cylindrical roller bearing, it can reduce internal differential sliding friction compared to a SRB and absorb roll shaft bending. (Permissible misalignment; 12min)

2. Smoothly releases roll extension

Smooth relief of roll extension under high temperature condition.

3. Improved handling (non-separating structure using retaining ring)

Easy bearing mount by non-separate design with snap ring on inner ring.

Product Benefits

Compared to previous models, this product has three times longer life when used in the severe environment of continuous casting machine guide rolls, and make a contribution to improve steel productivity.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue